WELCOME TO XLINK

Quality Control

XLink always keeps the faith of "win-win cooperation and sustainable development", and takes the stable high quality of products as the top priority in our management. From the warehousing of raw materials, to the production of semi-finished products and delivery of finished products, every production process is managed with strict quality standards and testing procedures. The products meet national eco-friendly protection requirements and many domestic and international certification standards.

XLink has a professional quality management team and a full range of testing equipment. Products of each batch are well recorded and monitored through daily collection and analysis of product data. The Application Technology Department and the active and timely after-sales service team of XLink further ensure the quality stability of products after delivery.

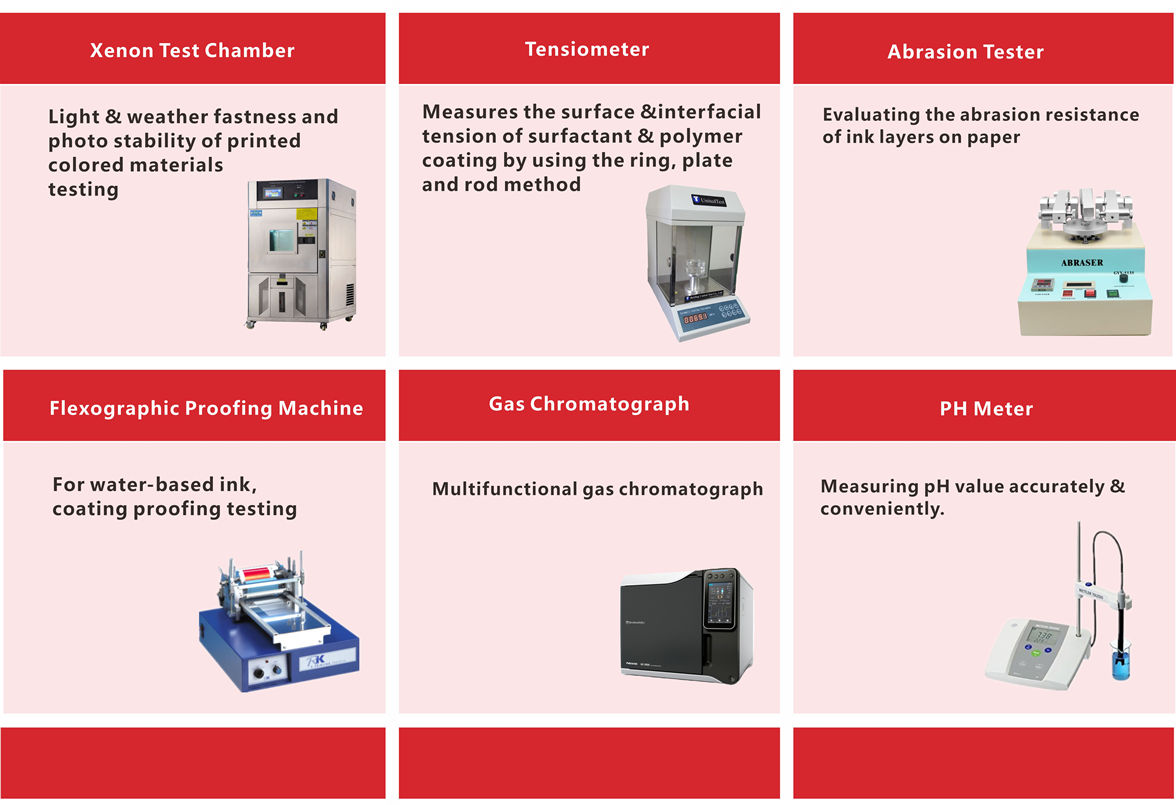

Test Facilities

XLink has professional equipments for different product test. Annual investment for R&D team, QC department and advanced testing equipment is more than 5 millions. There are 2 Flexographic Proofing Machines, 2 Xenon Test Chambers, 3 Ion Chromatographs, 5 Densitometers, 3 Abrasion Testers, 3 Tensiometers, 2 Gas Chromatographs, 5 PH Benches, 3 Flexo Proofing Machines.