WELCOME TO XLINK

Production Capacity

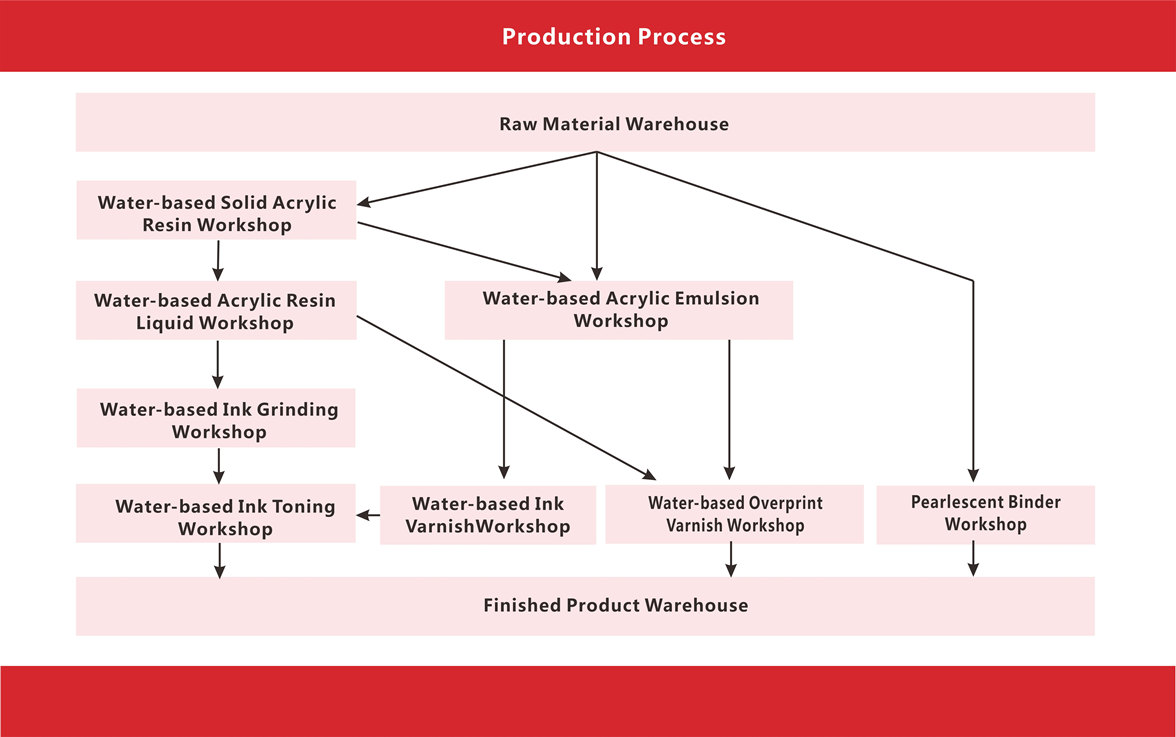

XLink's production base has a complete production line, covering the raw material storage, production of semi-finished and finished products, and packaging and storage of finished products. Three constant temperature raw material warehouses and nine production workshops are set up according to the storage requirements of different raw materials and production requirements of different products. Among them, the production process of food contact ink is in strict accordance with Good Manufacturing Practices (GMP), and the raw materials in direct contact with food have special marks.

Most of the production equipment in workshops are semi-automatic and fully automatic equipment, which can reduce manual operation, make the production process more eco-friendly, energy-efficiency and more precise, enhance the productivity and ensure the stability of products quality. The company's total annual output exceeds 30,000 tons, and the designed annual production capacity can reach 50,000 tons.

16,000

Water-based Solid Acrylic Resin(ton)17,000

Water-based Ink (ton)5,000

Water-based Varnish(ton)10,000

Water-based Polymer(ton)20,000

Water-based Solid Acrylic Resin(ton)20,000

Water-based Ink (ton)10,000

Water-based Varnish(ton)15,000

Water-based Polymer(ton)

Manufacturing Equipment

- Fully Automatic Resin Emulsion Acrylic Synthesis Reactor

Polymer emulsion is an important component of water-based ink and water-based varnish. Computer room centrally controls reactor operation to provide high-efficient productivity and ensure the quality stability

- Automatic ink dispenser

Formula management, efficient and stable, saving materials and improving productivity

- Automatic batching tank

Integrated control of mixing system, dynamic and continuous mixing , intelligent weighing and collection, cyclic and automatic recycling of dust

- Auto-dispersion equipment

Efficient intelligent sensors monitor the pressure and temperature of materials to ensure the quality and fineness of products.

- Large storage tanks

Large storage tanks, for unified control of the storage quality of semi-finished products and finished products

- Raw materials warehouse

Ensure the temperature sensitive raw materials are stored within the effective storage temperature range

- Auto Production Line

Semi-auto and fully auto production line, more efficient and stable production.

- Large storage tanks

Large storage tanks control the storage quality of semi-finished products and finished products