WELCOME TO XLINK

If the label printing enterprises adopt different brands and models of flexographic press, the diameter, length and other parameters of anilox roll will be different. In order to realize the exchange of flexible parts between different flexographic presses, it is necessary to deal with the relationship between anilox rollers, and regularly manage the anilox rollers, especially the verification of BCM value. Through BCM value of anilox roll, the ink consumption is accurately estimated, and the cost is further refined.

Generally speaking, anilox roll management includes daily maintenance, BCM value verification and color density measurement.

1. Daily maintenance

At present, label printing enterprises pay special attention to the daily maintenance of anilox roll, because the price of anilox roll is not only expensive, but also the accuracy directly affects the thickness and color of the ink layer. Take my company as an example, about 90% of the loss of anilox roll comes from improper daily maintenance, most of which are damaged in daily handling; and the damage caused by friction with scraper is very few, only when the flexographic press is printing long version loose parts, it needs to be opened 20 hours a day, and the same anilox roll is used for a long time, such damage will occur.

Therefore, it is necessary for label printing enterprises to formulate rules and regulations for the daily storage, use and cleaning (including online cleaning and offline ultrasonic or sandblasting cleaning) of anilox roll, such as the cleaned anilox roll needs to be wrapped with leather cover before being put back into the anilox roll stand. The attitude of the manager and the executive ability of the operator are needed for the daily maintenance of the anilox roll.

Only the operator strictly abides by, can guarantee the flow smoothly, reduce the loss.

2. Verification of BCM value

For a new anilox roll, in the first six months of use, the BCM value of the decay is the fastest. Therefore, the BCM value of anilox roll before it is put on the machine must be controlled. Here are two methods to verify BCM value of anilox roll

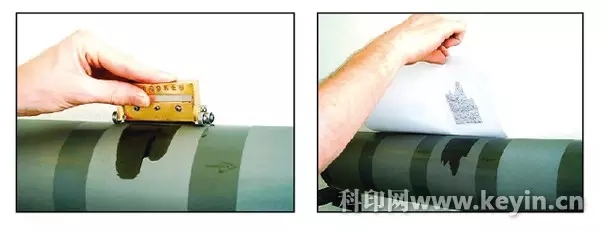

(1) BCM definition measurement method

BCM defined measurement method is an early practical measurement method. Firstly, the measuring ink of unit volume is injected into the anilox roll, and then the ink is slowly and evenly scraped off by the testing scraper. Then, the A4 copy paper is pressed on the anilox roll by hand, and the ink is transferred by means of pressure. Finally, a special measuring instrument is used to measure the transferred ink volume on the A4 copy paper, which is equivalent to the ink area on the anilox roll. The BCM value of anilox roll is obtained by dividing the unit volume of ink by the ink area on the anilox roll. This special roller ink load measuring instrument can be bought in Praxair and apex, and the general price is about 20000 yuan.

This method is easy to learn, but the operator needs a certain amount of time to practice repeatedly, which takes a long time. Generally, the operator must practice for 4-8 hours first, and then the measurement error can be controlled in a small range after the action is skillful, but the error is still about 3%. In the actual measurement process, a skilled operator can measure and calculate the BCM value of anilox roll within 10 minutes.

(2) three dimensional optical measurement

The three-dimensional optical measurement method is usually used by anilox roller manufacturers. Its advantage is that it can accurately measure the BCM value of anilox roller, but the required testing instruments are expensive. Generally, label printing enterprises do not need to purchase this kind of measuring instrument. When necessary, they can negotiate with the anilox roll manufacturer to send the anilox roll back to the manufacturer for measurement.

The three-dimensional optical measurement method directly measures the mesh volume, while the BCM definition measurement method is to measure the volume of a specific area of the anilox roll under the action of a specific measuring ink. Both methods measure the volume, there is a common problem: the ink load of anilox roller is not equal to the ink transfer.

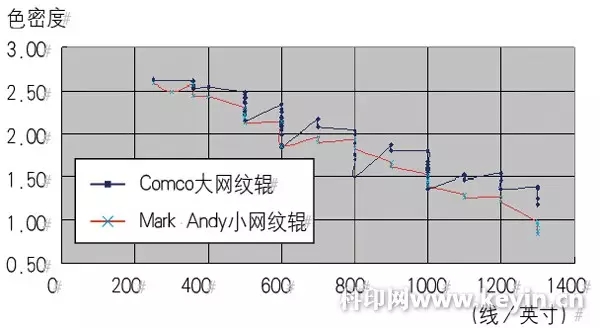

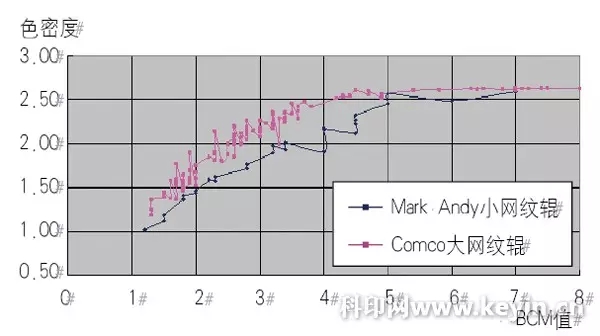

For example, the number of lines marked by an old anilox roll is 500 lines / inch, BCM value is 4.0, and the verified BCM value is only 3.4; the number of lines marked by a new anilox roll is 600 lines / inch, BCM value is 3.5. If you make the same amount of ink transfer comparison, the old anilox roll printed product color is not lighter than the new anilox roll. This is because the mesh surface area of 500 lines / inch anilox roll (less mesh wall) is larger than that of 600 lines / inch anilox roll, so that the contact area between ink and printing plate is larger. And the mesh opening rate of roller with 500 lines / inch and BCM value of 3.4 is small, and its ink transfer rate is naturally higher than that of roller with 600 lines / inch and BCM value of 3.5. It can be seen from the relationship between the color density of anilox roll with the same number of lines and different BCM values: the color density of the anilox roll with 1000 lines / inch can reach 1.7, but the minimum color density of the anilox roll with 800 lines / inch is only 1.5. The minimum color density of the Mark Andy small diameter anilox roll is 1.5, and that of the Comco large diameter anilox roll is 1.7; the color density of the Comco large diameter anilox roll at the BCM value of 1.8 can be 1.8, which is higher than that of the BCM value of 2.0. The reason is that the transfer rate of the anilox roll is different.

Even if the anilox roll is made by the same manufacturer, the ink color of a large-diameter anilox roll with a line number of 600 lines / inch and BCM value of 3.5 on a Comco flexographer is darker than that of a small-diameter anilox roll with a line number of 600 lines / inch and BCM value of 3.5 on the mark Andy 2200. This is also because the contact area between the large diameter anilox roll and the plate is larger than that between the small diameter anilox roll and the plate.

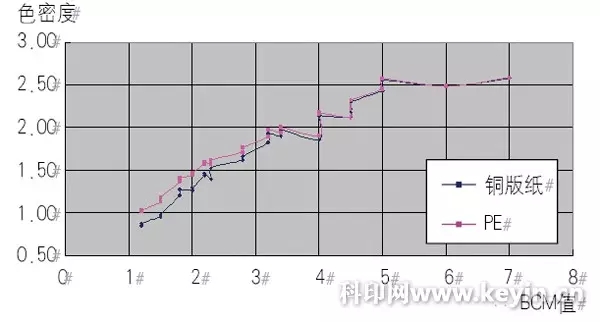

Even if it is the same anilox roller, when printing different substrate, its ink transfer rate is also different. Generally, the ink transfer rate of paper substrate is 28% ~ 35%, the ink transfer rate of film substrate is 26% ~ 27%, the difference between them is 5% ~ 8%. Because the ink absorption of paper substrate is high, the ink transfer rate is high. But the ink seeps into the inside of the paper, leaving less ink on the surface, resulting in a smaller color density.

With the verification of BCM value of anilox roll, it seems that the status of anilox roll is all under control, but it is not. As the ink carrying capacity of anilox roll is not equal to the ink transfer capacity, so for the captain, the ink transfer capacity of anilox roll is the most concerned. It will be the most practical verification method to print the anilox roll after BCM value verification under the same conditions, and measure the color density of the print, and then infer the new BCM value of the anilox roll.

3. Color density test method

Test tools:

① measure the pressure star, and prevent the pressure bar of ink bar;

② spectrophotometer;

③ for the most commonly used substrate, each anilox roller uses about 10 meters of substrate.

Test conditions:

Printing speed is the same (normal printing speed is OK), scraper is the same, ink is the same (blue ink is selected), substrate is the same, only the parameters of anilox roller are different.

Test methods:

Use spectrophotometer to measure the color density value of 20 color blocks on the printed matter. It is recommended to measure each color block 3 times and take the average value of color density.

Test results:

① the uniformity of BCM value of the anilox roller can be evaluated by the density value of 20 color blocks. If the difference between the maximum color density value and the minimum color density value is greater than 0.05, it means that the evenness of anilox roller is not good; if the difference is greater than 0.1, it means that the anilox roller can be cancelled.

② based on the verification of BCM value, the new BCM value can be inferred by color density.

For the captain, it is OK to recognize the BCM value only for the ink depth of the printed matter. It is not necessary to spend more energy to consider the relationship between the ink carrying capacity of the anilox roller and the ink transfer capacity.

For label printing enterprises with multiple brands of flexographic press, the above method can be used to calculate BCM value of anilox roll. Then, the same print in different flexographic printing machine printing, you can easily choose anilox roll.

This article is reproduced in the wechat public account of "soft India". If there is any infringement, please contact us to delete it.